![]()

ผู้นำเครื่องมือวิจัยแบบ Pilot Scale, Lab Operation Unit เครื่องกลั่นผลิตภัณฑ์ปิโตรเลียม ปิโตรเคมี โพลิเมอร์ พลาสติค น้ำมันเชื้อเพลิง น้ำมันหล่อลื่น ไบโอดีเซล ก๊าซโซฮอลล์ สารเคมี แวกซ์ เป็นต้น นอกจากนี้ยังครอบคลุมการกลั่นตัวทำละลายและสารเคมีเพื่อนำกลับมาใช้ใหม่ได้ รวมทั้งการสกัดสาร หัวน้ำหอม การแยกสารสมุนไพร สารสกัด สารสำคัญ การทำให้สารบริสุทธิ์ การทำให้สารเข้มข้น ด้วยเทคนิคหลากหลาย เครื่องดังกล่าวเหมาะกับสถาบันการศึกษา หน่วยงานวิจัย โรงพยาบาล โรงงานเครื่องสำอาง โรงพิมพ์ เป็นต้น

เครื่องมือแบ่งออกเป็นหมวดหมู่ดังต่อไปนี้

- เครื่องทดสอบสมดุลไอของของเหลว Vapour-Liquid-Equilibrium Apparatus

- ชุดเครื่องกลั่น / หอกลั่น ภายใต้ความดันบรรยากาศ และภายใต้ระบบสุญญากาศ Distillation Systems / Pilot Plants

- ชุดเครื่องกลั่นน้ำมันดิบ Crude Oil Distillation Systems

- เครื่องทดสอบค่าการหล่อลื่นของน้ำมัน (Lubricity Tester )ตามมาตรฐาน ASTM D 5001 Lubricity Tester

- เครื่องระเหยสาร/ เครื่องทำให้บริสุทธิ์/เครื่องทำสารเข้มข้นด้วยหลักการ Thin-Film-Evaporation Thin-Film-Evaporation

- เครื่องแยกสารด้วยวิธีการสกัด Separation by Extraction

- เครื่องมือวิเคราะห์การดูดซับและการคาย Sorption / Desorption

- ชุดอุปกรณ์ประกอบการเรียนการสอนระบบการนำความร้อน / การส่งถ่ายความร้อน / การไหลของของเหลว Heat Transfer System

- เครื่องผลิตและเครื่องวัดค่าโอโซน Ozone Generation

- อุปกรณ์ประกอบสำหรับชุดเครื่องกลั่นอัตโนมัติ Distillation Controller

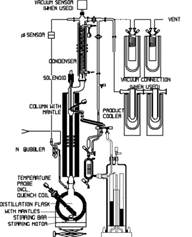

| VLE 100 Vapour-Liquid-Equlibrium (เครื่องทดสอบสมดุลไอของของเหลว) |

The vapour-liquid phase equilibrium of mixtures with two or more components are an essential basis for determining the theoretical number of separation stages and other distillation conditions. |

|

|

|

ชุดเครื่องกลั่น / หอกลั่น ภายใต้ความดันบรรยากาศ และภายใต้ระบบสุญญากาศ |

|||

| MRS 255 Micro-Distillation (ชุดเครื่องกลั่น / หอกลั่น ภายใต้ความดันบรรยากาศ และภายใต้ระบบสุญญากาศ – ปริมาณตัวอย่างน้อย) |

With concentric tube column MRS 255. Apparatus for fractionation of small charge quantities. The special advantage of the concentric-tube-column are:

The separation efficiency in the concentric-tube-column is based on the physical principle of the mass transfer between vertically rising vapour and the spirally trickling film of liquid in a concentric annular gap made of glass. The column consists of two concentrically melted-in, especially selected and calibrated glass tubes. |

|

|

| HRS 300 C Semi-micro distillation (ชุดเครื่องกลั่น / หอกลั่น ภายใต้ความดันบรรยากาศ และภายใต้ระบบสุญญากาศ – ปริมาณตัวอย่างน้อย) |

With concentric-tube-column HRS 300. Especially versatile unit with highest separation efficiency and up-to-date processor control. The special advantages of the concentric-tube-column are:

The separation efficiency in the concentric-tube-column is based on the physical principle of the mass transfer between vertically rising vapour and the spirally trickling film of liquid in a concentric annular gap made of glass. The column consists of two concentrically melted-in, especially selected and calibrated glass tubes. |

|

|

| HRS 500 C Semi-micro distillation (ชุดเครื่องกลั่น / หอกลั่น ภายใต้ระบบสุญญากาศ – ปริมาณตัวอย่างน้อย) |

With concentric-tube-column HRS 500. Especially versatile unit with highest separation efficiency and up-to-date processor control.The special advantages of the concentric-tube-column are:

The separation efficiency in the concentric-tube-column is based on the physical principle of the mass transfer between vertically rising vapour and the spirally trickling film of liquid in a concentric annular gap made of glass. The column consists of two concentrically melted-in, especially selected and calibrated glass tubes. |

|

|

| PILODIST 102 Universal distillation (ชุดเครื่องกลั่น / หอกลั่น เอนกประสงค์) |

Universal distillation apparatus made of glass for the production of products in utmost purity. The system can be supplied either with a wire gauze trickling column DN 25 or a concentric-tube-column (or both together for alternative use) according to requirements. Gentle distillation by temperature controlled oil bath with product circulation. Operation range from ATM down to vacuum. Equipped with processor based distillation control device DCD4001 with heating controller for oil bath and heating mantle, automatic reflux control, vacuum controller. |

|

|

| PILODIST 104 Versatile distillation system (ชุดเครื่องกลั่น / หอกลั่น เอนกประสงค์)

|

Versatile distillation system with high separation efficiency. The system is supplied with 2 different column types (DN 25), a concentric-tube-column and a wire gauze trickling column, which can alternatively be applied according to requirements. Gentle distillation by temperature controlled oil bath with product circulation. Operation range from ATM down to vacuum. This distillation system can be operated by using a single final receiver or alternatively by using a spider type automatic fraction collector with 6 receivers of 1 L volume each. Equipped with processor based distillation control device DCD4001 with heating control for oil bath and heating mantle, automatic reflux control, vacuum control, fraction collector control as well as safety devices. |

|

|

| PILODIST 105 Versatile distillation apparatus (ชุดเครื่องกลั่น / หอกลั่น เอนกประสงค์) |

Versatile distillation apparatus with high separation efficiency. The system is designed for automatic operation and includes an automatic fraction collector. The fraction changes resp. the receiver changes are automatically carried out according to pre-selected boiling temperatures or when the receivers are filled up. The vacuum-tight fraction collector contains 9 receivers and provides an overfill protection for each receiver. The receiver volume is related to the flask size. The system is supplied with 2 different column types (DN 25), a concentric-tube-column and a wire gauze trickling column, which can alternatively be applied according to requirements. Gentle distillation by temperature controlled oil bath with product circulation. Operation range from ATM down to vacuum. Equipped with processor based distillation control device DCD4001 with heating controller for oil bath and heating mantle, automatic reflux control, vacuum controller and controller for the automatic Fraction collector. |

|

|

| PILODIST 106 Versatile distillation system (ชุดเครื่องกลั่น / หอกลั่น เอนกประสงค์) |

Versatile distillation system with high separation efficiency. The system is supplied with a wire gauze trickling column (DN 50) with a packed height of 1000 mm. Gentle distillation by temperature controlled oil bath with product circulation. Operation range from ATM down to vacuum. Equipped with processor based distillation control device DCD4001 with heating control for oil bath and heating mantle automatic reflux control, vacuum control, fraction collector control as well as safety devices. |

|

|

| PILODIST 107 Recovery Unit (เครื่องกลั่นสารเคมี , ตัวทำละลาย เพื่อนำกลับมาใช้ใหม่ หรือ เครื่องกลั่นรีไซเคิลสารเคมี ,ตัวทำละลาย) |

Solvent Recovery Unit with Concentric-Tube-Column. PILODIST 107 is an easy to handele solvent recovery system for extremely pure solvents. The solvent mixtures are side products of extraction’s, washing processes, chemical and biochemical reactions, chromatographic operations in clinical range, especially in anatomical and pathological institutes. The system is equipped with a Concentric-tube-column, i.e. highest separation efficiency and high load ranges. |

|

|

| PILODIST 250 esp. for training students (เครื่องกลั่นสารเคมี , ตัวทำละลาย เพื่อนำกลับมาใช้ใหม่ หรือ เครื่องกลั่นรีไซเคิลสารเคมี ,ตัวทำละลาย [สำหรับประกอบการเรียนการสอน] ) |

Computer controlled distillation system for continuous operation. The system is designed especially for training students in process engineering/thermodynamics at universities. The system equipped with a DN 50 Packed or bubble cup tray column with 5 – 10 build in trays. The bubble cup column can be additionally equipped with temperature and sample nozzles on each tray. The distillation parameters are recorded and indicated on screen and can be stored permanently as recipes and recalled at any time. |

|

|

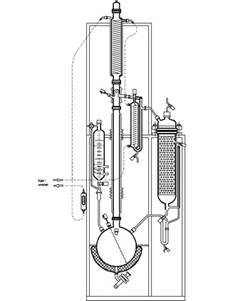

| PILODIST 254 Crude oil pilot plant (เครื่องกลั้นน้ำมันดิบภายใต้ระบบสุญญากาศ) |

Crude oil pilot plant for studying purposes or for simulation of the operation conditions in industrial-scale crude oil refineries or low-scale production plant. Distillation system with 5 bubble cap tray columns DN 100 with 10 plates as main column and max. 3 side columns (option) DN 50 with 5 plates each. Continuous operation, separation into boiling cuts by taking off the top product, max. 3 side products and the residue from the reboiler. Fully automatic operation due to freely programmable control. Reduction of the boiling point by stripping with superheated, unsaturated steam at atmospheric conditions or under vacuum. At every second plate sample take-off nozzles and temperature sensors are installed for determination and recording of concentration- and temperature profiles. Mass- and energy balances can be obtained by computer station with print-out of the distillation report by a printer. The system will be supplied together with a mounting frame and all necessary accessories. The installation requires a suitable hall with platforms and stairs as well as nitrogen, water and electricity.

|

||

| PETRODIST 500 Q semi-automatic (ชุดเครื่องกลั่นน้ำมันดิบ แบบกึ่งอัตโนมัติ ตามมาตรฐาน ASTM D 2892) |

Following an increasing demand for crude oil distillations to analyze small quantities in a short period of time PILODIST has modified the existing HRS 500 system to be applied for the purpose of crude oil distillation at a very attractive price. |

|

|

| PETRODIST 100 M manual, ASTM D-2892 (ชุดเครื่องกลั่นน้ำมันดิบ แบบ manual ตามมาตรฐาน ASTM D2892) |

Computer controlled crude oil distillation system for semi-automatic operation according to ASTM D-2892. The system is designed for automatic operation of the individual distillation stages, the fraction changes resp. the receiver changes are automatically carried out according to pre-selected boiling temperature or when the receivers are filled up. The vacuum-tight fraction collector contains 9 receivers. The receiver volume is related to the flask size. There are 9 receivers for every distillation stage, thus max. 36 fractions can be obtained with the usual 4 distillation stages. Distillation control device 4001 Computer-controlled Device for PILODIST Distillation systems with all necessary and peripheral components. Contains the operation and control elements for all parameters like temperature, vacuum, reflux divider, limit and alarm system, fraction collector. The actual parameters can be displayed in graphical curves to inform the operator about the actual status. The set parameters can be saved as recipes and reloaded. The control system is based on a multifunctional serial bus system, connected to a PC with our new and most modern windows based operation software. The distillation control device comes along complete with all operation software, PC and interface box as central connection point for all sensors. The installation requires water, nitrogen, compressed air and electricity. |

|

|

| PETRODIST 100 S semi-automatic, ASTM D-2892 (ชุดเครื่องกลั่นน้ำมันดิบ แบบกึ่งอัตโนมัติ ตามมาตรฐาน ASTM D 2892) |

Crude oil distillation system for semi-automatic operation exactly according to ASTM D-2892 (TBP). The system is designed for automatic operation within each of the following distillation runs:

After each run, the system stops automatically and the flask temperature has to be cooled down prior to the next distillation run. The operator has to enter the parameters for the next run to restart operation. The system contains a vacuum tight automatic fraction collector with 9 receivers for each run, which have to be replaced after each distillation run. The receiver change is performed according to pre-selected boiling temperature or when a receiver is filled up. |

|

|

| PETRODIST 100 CC fully automatic, ASTM D-2892 (ชุดเครื่องกลั่นน้ำมันดิบ แบบอัตโนมัติ ตามมาตรฐาน ASTM D 2892) |

Turn Key Processor controlled crude oil distillation system for fully automatic operation according to ASTM D-2892. Compact design with control system and safety items for unattended operation. No operator intervention and no intermediate stops are required. The distillation ensues automatically from the gas cut (IBP) to the pre-selected end point without any interruptions and any interventions. The yield calculation refers to the weight of the flask charge. The weights of the fractions are detected by means of a build in electronic balance prior to the discharge from the system into the fraction collector. The system can alternatively be equipped with a volume follower for volume detection. A data station for overriding parameter input as well as for display and print-out of all operation parameters, distillation results and TBP-curve, as well as an external balance is included. The system is modularly constructed and provides the possibility to allow several options like water removal (prior to the start of the distillation), stainless steel flasks, gas detector, hydrogen sulfide-alarm and trap as well as a complete sheating of the system. The TBP-curve will then be printed out in weight and volume percent. All necessary accessories will be supplied together with the system. The installation requires water, nitrogen, compressed air and electricity.

|

|

|

| PETRODIST 200 S semi automatic, ASTM D-5236 (ชุดเครื่องกลั่นน้ำมันดิบ แบบกึ่งอัตโนมัติ ตามมาตรฐาน ASTM D 5236) |

Crude oil distillation system for semi automatic operation according to ASTM D-5236 (Standard Test Method for Distillation of heavy Hydrocarbon Mixtures, Vacuum Potstill Method). The cuts are taken automatically according to the pre-selected boiling temperature or when the receivers are filled up. The vacuum tight fraction collector contains 9 receivers, their volume is related to the flask size. The control of the flask heating ensues either isothermally or according to the temperature difference between heating bath and flask. Thus an operation according to distillation rate is possible. All necessary accessories will be supplied together with the system. The installation requires water, nitrogen, compressed air and electricity.

|

|

|

| PETRODIST 200 CC fully automatic, ASTM D-5236 (ชุดเครื่องกลั่นน้ำมันดิบ แบบอัตโนมัติ ตามมาตรฐาน ASTM D 5236) |

Turn key processor controlled crude oil distillation system for fully automatic operation according to ASTM D-5236 (Standard Test Method for Distillation of Heavy Hydrocarbon Mixtures, Vacuum Potstill Method). The system is designed for unattended operation (during the distillation), the safety devices are designed accordingly. Data station for data input as well as for display and print out of all operation parameters, distillation results and distillation curve. The distillation ensues automatically from the start to the pre-selected or detected end point. The distillate volume is automatically recorded by means of an integrated volume follower system. The volume is measured separately on every individual receiver. The unit does not contain any intermediate receiver i.e.: to avoid reblend of the distillate. The volume calculation is expressed as percentage corresponding to the weight and the volume of the flask charge or total recovery. The distillation curve is printed out in weight and volume percent. The fraction changes are carried out automatically, alternatively according to a pre-selected boiling temperature or distillate volume or when the receivers are filled up. The vacuum-tight fraction collector contains 12 receivers with a capacity related to the flask size. The boil up rate is controlled according to a pre-selected distillation rate in ml/min. An accurate vacuum control guarantees the required stability of the distillation pressure. All necessary accessories will be supplied together with the system. The installation requires water, nitrogen, compressed air and electricity. |

|

|

| PETRODIST 200 CC / HV Distillation, ASTM D-5236 (ชุดเครื่องกลั่นน้ำมันดิบ แบบกึ่งอัตโนมัติ ตามมาตรฐาน ASTM D 5236) |

Distillation system conforming to ASTM D-5236 (Potstill). Automatic equipment with computer control system and automatic fraction collector. Fractionation of crude residues or high boiling components. The automatic fraction collector and the vacuum equipment are specially designed for the High-Vacuum (HV) – operation, and is equipped with 12 receivers, heated by IR-radiators. The flask heater is controlled either isothermally or according to the temperature difference heating mantle/flask, i.e. the system operates according to a determined indirect distillation rate, or according to direct distillation rate. The distillation procedures can be performed in the vacuum range: 10 – 0.006 mmHg. The final data and the Potstill distillation curve in wt-% and vol-% are printed out after reweighing the receivers and the residue (if the OPTION “evaluation system“ is connected). The PETRODIST 200 CC / HV is micro-processor controlled and ready for use, based on operator’s design. |

||

| PETRODIST 300 CC – F fully automatic, D-ASTM 1160 (ชุดเครื่องกลั่นน้ำมันดิบแบบอัตโนมัติ) |

Fully automatic crude oil distillation system, processor controlled according to ASTM D-1160 but with automatic fraction collector for the determination of boiling ranges of crude oil products under vacuum. The system can be operated in strict accordance to the ASTM procedure with 1 single receiver or alternatively, by using the automatic fraction collector, with 4 receivers. Key features of PETRODIST® 300 CC-F

The distillation is fully automatic from the initial boiling point to the pre-selected end boiling point or detected break-off. The criteria for break-off are:

The distillation volume is measured automatically in receivers, temperature controlled by an IR-heater. The yield is calculated in percentage to the charge quantity. Distillation report, final data and distillation curve are printed out. |

|

|

| PETRODIST 300 CC fully automatic, ASTM D-1160 (ชุดเครื่องกลั่นน้ำมันดิบแบบอัตโนมัติตามมาตรฐาน ASTM D 1160) |

Processor controlled Crude oil distillation system according to ASTM D-1160. System for determination of boiling ranges of crude oil products under vacuum in fully automatic operation. Special advantages of the new PETRODIST® 300 CC are

The distillation is automatic, from the initial boiling point to the pre-selected end boiling point or detected break-off. The criteria for break-off are:

The distillation volume is measured automatically in a tempered receiver. The yield is calculated in percentage to the charge quantity. Distillation report, final data and distillation curve are printed out. |

|

|

| PETRODIST 300 M manual boiling analysis (ชุดเครื่องกลั่นน้ำมันดิบ ตามมาตรฐาน ASTM D 1160) |

Manual boiling analysis system according to ASTM D-1160. The charge, depending on the distillate receiver temperature, has to be filled in the flask. The distillation is performed from the Initial Boiling Point (IBP) to the End Boiling Point (EBP) by the operator. The criteria for a distillation end are:

The distillate volume is measured by the operator in a temperature controlled receiver. |

|

|

| PETRODIST 400 A Comb. Systems (ชุดเครื่องกลั่นน้ำมันดิบแบบอัตโนมัติแบบรวมสองระบบในเครื่องเดียว ตามมาตรฐาน ASTM D 2892 และ D 5236) |

Processor controlled and combined crude oil distillation system for automatic operation according to ASTM D-2892 (TBP) and ASTM D-5236 (Potstill). PETRODIST 400 A is a combination of the basic systems * PETRODIST 100 S * PETRODIST 200 CC One of both systems can be operated at a time. The system enables to perform TBP- and Potstill – distillations of various crude samples according to ASTM-standards and is designed for laboratory use. The system is equipped with a central computer control, vaccum supply and thermostate system, data storage and evaluation station as well as a fraction collector, designed to serve for both distillation systems alternatively and provides direct automatic distillation flow rate control. The fraction/receiver changes are automatically performed according to preselected cut temperatures or in case of receiver overfilling. The fraction collector is equipped with 12 receivers. The final data and the TBP-curve in wt% and vol% are printed out after reweighing the residue. The distillation acc. to ASTM D-5236 is fully automatic without any interruption from the beginning till the complete termination of the distillation. The system part for distillation acc. to ASTM D-2892 needs a change of receivers after each of the different pressure runs due to the design of the fraction collector to serve for both distillation systems. The unit requires water, nitrogen, compressed air and electricity. Dry ice or liquid nitrogen is required for cold traps. |

|

|

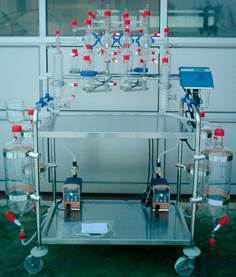

| PETRODIST 400 CC Comb. Systems (ชุดเครื่องกลั่นน้ำมันดิบแบบอัตโนมัติแบบรวมสองระบบในเครื่องเดียว ตามมาตรฐาน ASTM D 2892 และ D 5236) |

Processor controlled combined crude oil distillation system for fully automatic operation according to ASTM D-2892 (TBP) and ASTM D-5236 (Potstill). PETRODIST 400 CC is a combination of the following systems: PETRODIST 100 CC (ASTMD-2892) PETRODIST 200 CC (ASTM D-5236) Both systems can operate at the same time (simultaneously) in fully automatic, uninterrupted and unattended mode. The data evaluation software provides also a combined TBP-curve for both systems. Compact design with control system and safety items for unattended operation. No operator intervention and no intermediate stops are required. All necessary accessories will be supplied together with the system. The installation requires water, nitrogen, compressed air and electricity. The system enables to perform TBP- and Potstill – distillations of various crude samples according to ASTM-standards and is designed for laboratory use. The system is equipped with a central computer control, vaccum supply and thermostate system, data storage and evaluation station as well as a fraction collector, designed to serve for both distillation systems simultaneously and provides direct automatic distillation flow rate control. The fraction/receiver changes are automatically performed according to preselected cut temperatures or in case of receiver overfilling. Both systems are equipped with individual fraction collectors to allow simultaneous operation of both systems. The final data and the TBP-curve in wt% and vol% are printed out after reweighing the residue. The unit requires water, nitrogen, compressed air and electricity. Dry ice or liquid nitrogen is required for cold traps. |

|

|

| PETRODIST 400 S Comb. Systems (ชุดเครื่องกลั่นน้ำมันดิบแบบอัตโนมัติแบบรวมสองระบบในเครื่องเดียว ตามมาตรฐาน ASTM D 2892 และ D 5236) |

Crude oil distillation system for semi-automatic operation according to ASTM D-2892 (TBP) ASTM D-5236 (Potstill) The PETRODIST 400 S is a combination system for alternative operation of the following systems *PETRODIST 100 S * PETRODIST 200 S The central fraction collector is used for both PETRODIST 100 S as well as PETRODIST 200 S. The vacuum supply, the cryostat/ thermostat and the control station are also used for both systems. The unit requires water, nitrogen, compressed air and electricity. Dry ice or liquid nitrogen is required for cold traps. The cuts are taken automatically according to the pre-selected boiling temperature or when the receivers are filled up. The vacuum tight fraction collector contains 9 receivers. All necessary accessories will be supplied together with the system. The installation requires water, nitrogen, compressed air and electricity. |

|

|

|

เครื่องทดสอบค่าการหล่อลื่นของน้ำมัน(Lubricity Tester)ตามมาตรฐาน ASTM D 5001 |

|||

| PILODIST – BOCLE ASTM D-5001 (เครื่องทดสอบค่าการหล่อลื่นของน้ำมัน ตามมาตรฐาน ASTM D 5001 |

Test Equipment for Measurement of Lubricity of Aviation Turbine Fuels by the Ball-on-Cylinder Lubricity Evaluator according to ASTM D-5001. The BOCLE-equipment according to ASTM D-5001 measures the actual wear scar size with a Test Ball specimen. The wear scar is generated by the friction between the stationary ball and a rotating cylinder. A part of the rotating cylinder is immersed in the turbine fuel tank (50 ml) and covered with the turbine fuel. The temperature of the fuel tank is controlled, as well as the relative humidity of the air which is circulated into and above the test fluid – the air flow rate is controlled, too. The Test Ball is loaded by a preselected load for the test period 30 min. After the test the minor & major axis of the resultant wear scar are measured with a microscope. Two measurements have to be performed for getting an averaged result, the more lubricity a Turbine Fuel has the lower is the resultant wear scar.

|

|

|

|

เครื่องระเหยสาร/ เครื่องทำให้บริสุทธิ์/เครื่องทำสารเข้มข้นด้วยหลักการ Thin-Film-Evaporation |

|||

| FilmDist SP 200 universal lab-scale (เครื่องระเหยสาร/ เครื่องทำให้บริสุทธิ์/เครื่องทำสารเข้มข้นด้วยหลักการ Thin-Film-Evaporation) |

Universal lab-scale apparatus for shortpath evaporation. Rotary thinfilm evaporator with thermostat mantle and internal condenser for continuous shortpath distillation or gentle concentration of thermally sensible products. Suited for laboratory or pilot operation. The pilot operation data and experimental values can be transferred to bigger systems. The standard system uses glass wiper elements. Other wiper elements are available. |

|

|

| PILODIST SP 500 shortpath evaporator (เครื่องระเหยสาร/ เครื่องทำให้บริสุทธิ์/เครื่องทำสารเข้มข้นด้วยหลักการ shortpath evaporator) |

Shortpath evaporator apparatus for lab-scale or pilot operation. Rotary thinfilm evaporator with thermostat mantle and internal condenser for continuous shortpath distillation or gentle concentration of thermally sensible products. Suited for laboratory or pilot operation. The pilot operation data and experimental values can be transferred to bigger systems. The standard system uses PTFE rolling wiper elements. Other wiper elements are available. |

|

|

| FilmDist TF 650 thinfilm evaporation (เครื่องระเหยสาร/ เครื่องทำให้บริสุทธิ์/เครื่องทำสารเข้มข้นด้วยหลักการ Thin-Film-Evaporation) |

Universal apparatus for thinfilm evaporation for lab-scale and pilot-scale application, complete with all necessary accessories for continuous operation. Rotary thinfilm evaporator with thermostat mantle and external condenser. The model TF 650 is excellently suited for universal lab-scale and pilot-scale application and is completely equipped with all necessary accessories for the continuous operation. |

|

|

| PILOEX SLS 250/SR mixer-settler for liquid-liquid extraction (เครื่องสกัดของเหลวด้วยของเหลว โดยวิธี mixer-settler) |

This mixer-settler apparatus has been designed to study liquid-liquid-extraction processes. One part of the component, which has to be separated from the liquid phase (raffinate phase) is extracted by means of a liquid solvent (extract phase). This component is concentrated in the solvent (extract phase from the extraction phase to extraction phase). The raffinate phase and the extract phase will be led through the system in opposite directions. The advantage of the mixer-settler apparatus is the high efficiency of the exchange stages. Each stage consists of a mixer with downstream settler. In the mixer the light and the heavy phase from the neighbouring stages are brought together, are intensively mixed and then simultaneously conveyed into the settler. Due to the intensive mixing the phases are divided into drops, so that the greater exchange surface, the substance transfer from one phase to another is heavily intensified. Together with the component to be extracted, e.g. heavy phase, the raffinate phase is pumped from the raffinate store into the mixer of the last stage of the extractor. The solvent, e.g. light phase is pumped from the corresponding store tank into the mixer of the first stage of the extractor. Both phases, raffinate and extract are led into opposite directions through the extractor, the raffinate phase from the last stage and the extract phase from the first to the last extraction stage. On it’s way through the apparatus the component which is to be extracted, is increasingly separated from stage to stage. Simultaneously the solvent stream (extract phase) absorbes more and more of the extracted component. The raffinate phase from which the component has been extracted, leaves the extractor at the first stage and is collected in a collecting vessel. The extracted phase leaded with the extracted component leaves the extractor at the last stage and is collected in a collecting vessel. Contrary to other separation methods, the extraction will not directly lead to pure components. The extract phase is e.g. to be separated in a downstream distillation/rectification into extracted component and solvent. The advantage of the extraction is e.g. the lower consumption and the possibility of a primary separation of the components, which would not or would only be possible by distillation. |

|

|

| PILOEX PES Pulsated extractions system (เครื่องสกัดของเหลวด้วยของเหลว โดยวิธี Pulsated extractions)

|

Pulsating extraction columns are operated continuously counter current wise. In order to intensify the mass transfer between the phases, it is essential for the benefit of enlargement and regeneration of the exchange surfaces that the liquid phases are constantly broken up into droplets at the sieve plates and are subjected to intensive mixing as a result of the pulsating liquid column, for example by means of a membrane piston pump. Variation of the amplitude and/or the frequency of tuning the system for optimal drop distribution. The system is available with a column diameter of 50 or 80 mm and is designed for studying separation processes in industrial R & D – centres and universities |

||

| PILOEX SBC 01 with micro-extraction column (เครื่องสกัดของเหลวด้วยของเหลว โดยวิธี micro-extraction) |

Lab-scale unit with MICRO-EXTRACTION COLUMN SBC 01 for smallest charge quantities and continuous operation. The extraction spinning-band column made of glass is excellently suited for laboratory purposes. Its special advantages are low throughput at continuous operation and low hold-up. |

|

|

| PILOEX SL 5 solid-liquid extractor (เครื่องสกัดของแข็ง-ของเหลว โดยวิธี solid-liquid extractor) |

For application in universities, technical colleges for training students. The solvent circulates between extraction vessel, evaporator and condenser. The solid matter in the extraction vessel is continuously rinsed with purified solvent until all solubles are leached out of the solid matter. The solvent, which is charged with the extract, flows from the extraction vessel into the evaporator, where the extract will be collected and concentrated. After terminating the leaching process, a further purification of the extract by evaporation is possible. The system is designed for batch (discontinuous) operation but can also be operated semi-continuously. The standard system can be operated either for vacuum operation or overpressure operation as well. The system can be designed either in glass, stainless steel or other material, depending on the application. The following modes of operation can alternatively be carried out :

|

|

|

|

เครื่องมือวิเคราะห์การดูดซับและการคาย (Sorption / Desorption) |

|||

| PILOTADS 030 studying adsorption process (เครื่องมือวิเคราะห์การดูดซับและการคายสำหรับการเรียนการสอน) |

Continuously operating system for studying the adsorption process. The system is designed for training students in process engineering / thermodynamics at universities. The adsorption process can be shown with a mixture “wet air/dry air” or “Air/CO2 and active carbon or molecular sieve as adsorption material. The regeneration is performed by heating up the adsorption material combined with air stripping. An operation and tutor manual describing the adsorption theory and practice are included and will be delivered with the system. |

||

| PILOTADS 010 studying adsorption process (เครื่องมือวิเคราะห์การดูดซับและการคายสำหรับการเรียนการสอน) |

Continuously operating system for studying the adsorption process. The system is designed for training students in process engineering / thermodynamics in universities. The adsorption process can be shown with a mixture “wet air/dry air” or “Air/CO2 and active carbon or molecular sieve as adsorption material. The regeneration is performed by heating up the adsorption material combined with air stripping. An operating and tutor manual describing the adsorption theory and practice are included and will be delivered with the system. |

||

| PILOTABS 200 absorption/desorption (เครื่องมือวิเคราะห์การดูดซับและการคาย) |

Continuously operating system for studying the adsorption process. The system is designed for training students in process engineering / thermodynamics in universities. The adsorption process can be shown with a mixture “wet air/dry air” or “Air/CO2 and active carbon or molecular sieve as adsorption material. The regeneration is performed by heating up the adsorption material combined with air stripping. An operating and tutor manual describing the adsorption theory and practice are included and will be delivered with the system. |

||

|

ชุดอุปกรณ์ประกอบการเรียนการสอนระบบการนำความร้อน / การส่งถ่ายความร้อน / การไหลของของเหลว (Heat Transfer System) |

|||

| HTS 100 delivered ready for use (ชุดอุปกรณ์ประกอบการเรียนการสอนระบบการนำความร้อน / การส่งถ่ายความร้อน / การไหลของของเหลว) |

The HTS-system is equipped with a thermostat and is delivered ready for use. Required sources are: cold water from tap water supply, max. 500 L/H, max. pressure 2 bar, ambient temperature,power supply: 230 V, 50 Hz For demonstration of hydrodynamic and heat technical effects. The equipment is designed for studying and training of students in universities and technical colleges for studies of hydrodynamic and heat transfer effects and their mutual influences and dependence from each other. The basic design of heat exchangers is shown in theory and practice. Following examinations can be performed:

|

|

|

| Ozone generators OGF reliable laboratory/pilot plant (เครื่องวัดค่าโอโซนสำหรับแลป และห้องปฎิบัติการ) |

Portable ozone generators especially suited for reliable laboratory and pilot plant application; for oxygen and dried air as feedgas. High ozone concentration in oxygen. The ozone generating module is made of inert material and is build together with the power supply and the instrumentation into a 19” aluminium housing (protection class IP 42) with air cooling. The gas flow is adjustable at the needle valve of the flow meter. The electrical power consumption is shown at the LCD display. The ozone concentration can be regulated between 5 and 100 % by means of an electrical controller or an external signal. Generators available for different nom. ozone productions available:

|

|

|

| Ozone analyzer OPF 200 accurate UV-photometer (เครื่องทดสอบค่าปริมาณโอโซนด้วยระบบ UV-photometer) |

The OZON analyzer OPF 200 is an accurate UV-photometer for the continuous measurement of the ozone concentration in the range 0 – 200 g/m3 in the gas phase. The UV-system allows a measurement at 254 mm wavelength according DIN and IOA-Standard without any cross selection to other gas species. The instrument needs no moving parts and consists of single beam photometer. The UV-lamp has a very stable intensity and has to be replaced every 24 months. The analyser consists of an internal catalyser for the destruction of ozone in the sample flow. The unit is especially suited for ozone measurements at the output of ozone generators resp. ozone producing systems.

|

|

|

|

อุปกรณ์ประกอบสำหรับชุดเครื่องกลั่นอัตโนมัติ (Distillation Controller) |

|||

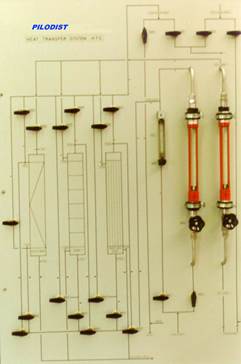

| DCD4001 Distillation Control Device (อุปกรณ์ประกอบสำหรับชุดเครื่องกลั่นอัตโนมัติ) |

Computer-controlled device for PILODIST distillation systems. For operation and control temperature, vacuum, reflux divider, limit and alarm system and fraction collector. The actual parameters can be displayed in graphical curves to inform the operator about the actual status. The set Parameters can be saved s recipes and reloaded. The control system is based on a multifunctional serial bus system, connected to a PC with our new and most modern windows based operation software. The DCD 4001 includes the operation software, a PC and the Interface box as central connection point for all sensors. |

|

|

| KW100 Cooling Water Safety Device (อุปกรณ์สำหรับต่อพ่วงระบบน้ำหล่อเย็น) |

Cooling water safety relay KW100 with digital indication of throughput and supervision of cooling water flow combined with best safety features, like solenoid stop valve alarm output and switch off of the connected apparatus. Audible alarm signal in case of cooling water failure which enables an immediate reaction by the operator. |

|

|